How to Clean Stubborn Fiber Out of a Drum Carder

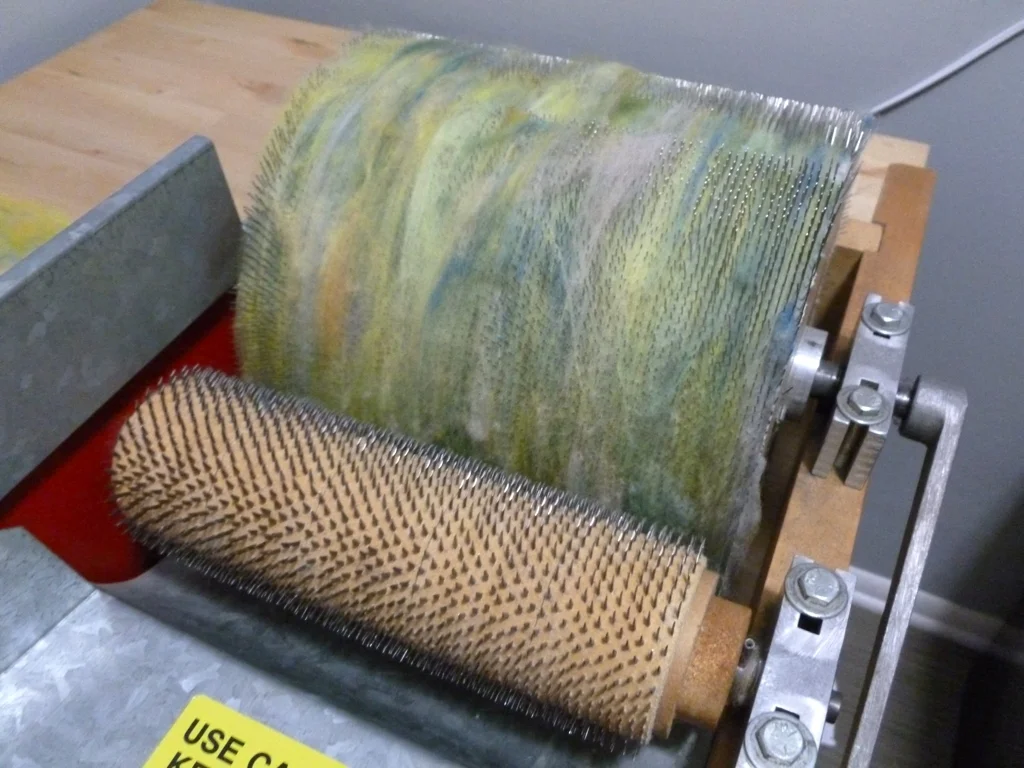

/My drum carder has been sitting unused and unloved for the past few months. Why? All this green fiber stuck in the tines. I bought 4 ounces of Corriedale wool locks, AKA the green fiber, to practice making batts and figure out the carder’s quirks. Making the batts turned out to be a struggle because the locks were matted, but I didn’t realize how matted until it was time to feed them into the carder. I had to crank the drum while pulling back on the fiber to get them to open and pull apart instead of just feeding onto the main drum in one big clump. I made 2 batts before calling it quits because the all the fiber stuck on the main drum. To make things even more aggravating, the stuck fiber only seemed to trap more fiber down there with it. The bent paper clip I attempted to pick the fibers out with didn’t do that great job and none of my other tools did a thing. So the carder went back on the shelf until I could figure out how to clean it.

The answer to my problem turned out to be in a blog post from 2009 (!) that listed the basic tools to use with your drum carder. Definitely worth a read if you’re thinking about getting your hands on a carder. Anyway, one of the recommended tools was a pair of long thin forceps, extra long tweezers, because they’re thin enough to get between the tines without damaging the carding cloth. So I picked up a pair at the hardware store.

This is what my carder looked like before:

And this is what the carder looked like after the 23 minutes I spent picking at with the forceps:

I didn’t pull off every bit of green since I’m going to try carding the rest of the fiber (it’s a point of pride and stubbornness now), but the difference is night and day. The forceps were great for picking up both small and large bits of fiber. Even better I was able to work them under the larger sections and push the fiber up so I could grab it.

Cleaning the the carder wasn’t quick, but the forceps did a great job. They grabbed every stuck strand big or small. Plus, I didn’t scrape or poke my fingers on the tines. Glad I’ve got the forceps as part of permanent drum carder cleaning kit. They’re cheap, work well, and don’t take up a lot of space. Get a pair.